The strut tower brace is a structural component connecting suspension to chassis, enhancing vehicle stability and cornering. Crafted from steel or aluminum, it strengthens front suspension, improves performance in diverse conditions, and integrates with systems like high-performance brakes and air intake. Choosing the right materials ensures longevity, especially with vehicular upgrades. Correct installation aligns components for optimal benefits, reducing body roll and improving handling.

Strut tower braces are essential components in automotive engineering, crucial for vehicle stability and handling. In this article, we explore how these components withstand extreme conditions, particularly corrosion and high temperatures. From understanding their construction to selecting durable materials, we provide insights on what makes a top-quality strut tower brace. Additionally, we offer practical installation tips to ensure optimal performance and longevity of your vehicle’s suspension system, emphasizing the significance of this often-overlooked yet vital part.

- Understanding Strut Tower Brace Construction

- Materials That Withstand Corrosion and Heat

- Installation Tips for Optimal Performance

Understanding Strut Tower Brace Construction

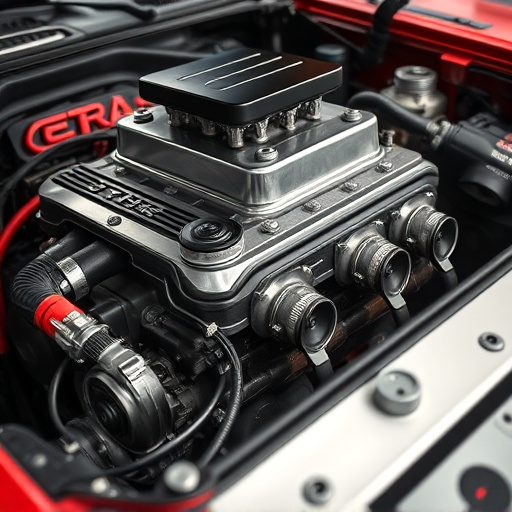

The strut tower brace, a pivotal component in automotive engineering, is designed to enhance structural integrity and stability. Its primary role is to connect the upper suspension assembly to the vehicle’s chassis, fortifying the front suspension and improving overall handling. This essential piece is typically crafted from high-grade metals like steel or aluminum, chosen for their exceptional strength and corrosion resistance. The brace’s construction involves strategic positioning of rigid tubes or rods that form a robust network, effectively reducing body roll and improving cornering abilities.

In modern vehicles, especially those with enhanced performance capabilities, the strut tower brace often aligns with other critical systems. For instance, it can serve as a mounting point for high-performance brakes, allowing for better heat dissipation during intense driving conditions. Moreover, when combined with upgraded air intake systems and suspension kits, the brace contributes to optimal vehicle dynamics, ensuring a smoother ride and enhanced performance across various terrains and climates.

Materials That Withstand Corrosion and Heat

When it comes to automotive components like a strut tower brace, choosing materials that can resist corrosion and high temperatures is paramount for longevity and safety. In this regard, steel alloys often top the list due to their exceptional strength-to-weight ratio and resistance to both rust and heat. Specifically, stainless steel and high-performance grade steels are preferred in manufacturing quality strut tower braces. These materials offer superior durability, ensuring the brace remains intact even under extreme conditions, such as when installing high performance parts like a cat back exhaust or upgrading brake pads.

The ability of these materials to withstand corrosion is particularly crucial for components that are constantly exposed to varying weather conditions and automotive fluids. Unlike some cheaper alternatives, stainless steel does not undergo galvanic corrosion when in contact with other metals, making it an ideal choice for strut tower braces that connect to various parts of the vehicle’s suspension system. Additionally, their heat resistance ensures the brace maintains its structural integrity during high-performance driving, thereby enhancing overall vehicle stability.

Installation Tips for Optimal Performance

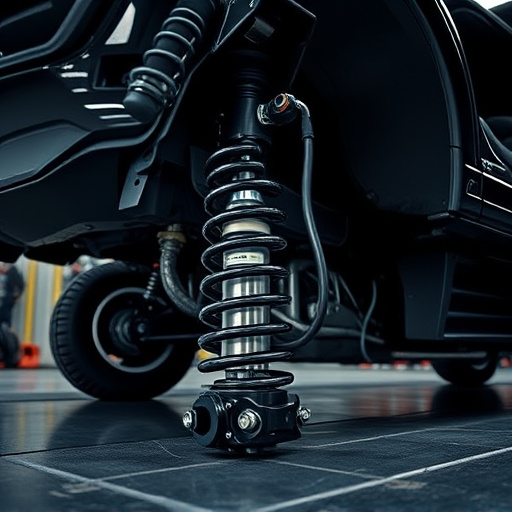

When installing a strut tower brace, proper alignment and tightening are key to achieving optimal performance. Ensure all bolts and connectors are securely fastened according to the manufacturer’s specifications. The brace should be rigidly attached to both the vehicle’s chassis and the strut tower for maximum strength. Proper installation ensures that the strut tower brace effectively reduces body roll, improving cornering precision and enhancing overall vehicle stability.

Remember, a strut tower brace is not just an add-on; it’s a critical component in upgrading your vehicle’s suspension system, especially when combined with high-performance parts like performance brakes. This simple modification can significantly impact driving dynamics, offering both enhanced handling and a more responsive ride, particularly on winding roads or tracks.

When it comes to enhancing vehicle stability and performance, a high-quality strut tower brace is an essential component. By understanding its construction, selecting materials resistant to corrosion and high temperatures, and following proper installation tips, you ensure optimal performance and longevity of your strut tower brace—a crucial investment for any car enthusiast looking to maximize their vehicle’s potential. Remember, a well-maintained strut tower brace can make all the difference on the road.